AR Greenhouses and Irrigation system

- amit rodoy

- Oct 8, 2025

- 10 min read

Dear visitor: This post outlines the choices for greenhouses, tunnels, nethouses, irrigation systems, control systems, and coverings.

If you find it interesting, please don't hesitate to reach out to us.

Close Gothic Greenhouses:

Gutter height up to 5 meters.

Width spans of 8, 9.6, 10, 11, or 12 meters.

Height under gutter can reach up to 5 meters, depending on the model.

Distance between arches:

Available in multiples of 2 or 4 meters.

Arch diameter:

02 inches.

Posts:

Profile size 80x80 mm.

Can withstand wind speeds of:

120 to 150 km/h.

Supports trellising loads up to:

25 kg/m².

NET HOUSES

Width 6 m - 8 m

Length multiples of 4 m - 5 m depending on the model

Height 3.0 m to 5 m depending on the model

Posts diameter 80 x 80

Withstands wind loads of: 120 km/h

Withstands trellis loads of up to: 25 kg/m²

TUNNELS:

The tunnels are ventilated from both ends, making them ideal for growing a variety of flowers and vegetables. The model's wide-open gable fronts, along with side ventilation, provide effective airflow within the tunnels. Gildan’s circular tunnels are designed to divert heavy rain, and their shape makes them perfect for regions with high wind speeds. The straightforward and quick assembly system requires no concrete, allowing the tunnels to be relocated with ease. Additionally, the design of this model enables it to be set up on sloped land.

Width - 6 m to 12 m

Length - Increments of 2 m to 3 m, based on the model

Height at the peak - Up to 4.5 m, depending on the model

Arch diameter - Ø1" to Ø2"

Roof vent opening - 1.2 m

Withstands wind speeds of 120 to 150 km/h

Trellising loads up to: 25 kg/m²

🌴 Tropical Greenhouse

A tropical greenhouse is a structure designed to establish a controlled microclimate ideal for crop cultivation in warm, humid, high-radiation regions such as Rwanda, East Africa, or Southeast Asia.

Its purpose is to cool and protect rather than heat, focusing on enhancing airflow, providing shade, and excluding pests.

🏗 1. Structural Design Features

✅ a) Roof Shape

Preferred designs include Gothic arch or vented tunnel.

The elevated roof (5–6 m at the ridge) facilitates convection, allowing hot air to rise and escape easily.

Continuous roof vents (ridge vents) or butterfly vents enable natural hot air release.

✅ b) Materials

Component Recommended Material Reason

Frame Galvanized steel or aluminum Resists corrosion in humid conditions

Covering (roof) UV-stabilized polyethylene film (150–200 microns) Provides good light diffusion and is cost-effective

Sidewalls 40–50 mesh insect net Enhances airflow and pest control

Optional panels Polycarbonate (for permanent, high-end facilities) Offers durability and insulation

✅ c) Gutter Height

A minimum of 4.5–5.5 m is recommended for large-scale operations.

This height improves thermal buoyancy and air mixing efficiency.

2. Ventilation and Cooling

a) Natural Ventilation

Cross ventilation is achieved through sidewall roll-up nets.

Roof ridge vents should cover 10–15% of the roof area.

Airflow is supported by 50” exhaust fans and circulation fans to avoid stagnant zones.

b) Evaporative Cooling (Pad & Fan System)

Cool, humid air is brought in through wet cooling pads and exits via exhaust fans.

This system can reduce the inside temperature by 6–10°C, depending on humidity.

c) Shading

Aluminet 50–60% external shade is used to decrease solar radiation.

An optional internal retractable shading curtain provides fine control.

3. Irrigation & Humidity Management

Drip irrigation combined with fertigation is recommended for precision and water efficiency.

Misting or fogging systems offer additional cooling and humidity stabilization.

Maintain relative humidity (RH) between 60–75%, depending on the crop.

4. Insect & Disease Control

Use 40–50 mesh insect-proof nets on all air inlets and vents.

Install a double-door entry airlock with insect netting.

Optionally maintain slight positive pressure inside by having fans blow filtered air in.

5. Automation & Climate Control

Modern tropical greenhouses often incorporate semi- or fully-automated systems:

Sensors: Monitor temperature, humidity, light, CO₂, and soil moisture.

Controllers: Automate the opening/closing of vents, shading curtains, and irrigation valves.

Data monitoring: Cloud-based systems enable remote control and analytics.

☀ 6. Energy Considerations

Reduce mechanical cooling load with passive design (orientation, vents, shading).

Install solar panels on roof edges or service buildings to power fans, pumps, and control systems.

Consider using thermal screens for night heat retention in high-altitude tropical zones.

8. Crop Suitability

Tropical greenhouses are suitable for:

Vegetables: Tomato, pepper, cucumber, lettuce, herbs.

High-value crops: Cannabis, strawberries, orchids.

Seed production: For export (with biosecurity compliance).

Glass Greenhouse Technology

1. Structural Design & Materials

Framing Materials: Aluminum and galvanized steel are popular choices due to their durability and corrosion resistance. Aluminum is lightweight and resistant to rust, whereas galvanized steel provides strength and long-lasting performance.

Glazing Materials: Tempered glass is favored for its strength and clarity, enabling maximum light penetration. Some greenhouses incorporate double-glazed units to enhance insulation.

Design Styles: Modern greenhouses typically showcase sleek, minimalist designs with sharp angles and clean lines, blending effortlessly into contemporary landscapes.

Heating systems:

🌿 1. Hot Water (Hydronic) Heating

How it functions:

A boiler (using gas, oil, or electricity) heats water, which is then circulated through pipes or radiators across the greenhouse.

The heat emitted from these pipes maintains the air and soil at ideal temperatures.

Provides consistent, gentle heating that minimizes plant stress.

Can be integrated with thermal storage systems.

Effective in large greenhouse environments.

High initial installation expense.

Requires regular upkeep of the boilers and pipes.

🌿 2. Forced-Air Heating

How it functions:

Fans and ducts are used to blow heated air into the greenhouse.

The air can be heated with gas, propane, or electric heaters.

The greenhouse space warms up quickly.

Specific areas can be targeted for heating.

Installation is simpler compared to hydronic systems.

The air may be dry, necessitating additional humidity control.

Heat distribution can be uneven if fans are not correctly positioned.

🌿 3. Radiant Heating (Infrared Panels)

How it works:

Infrared panels produce heat that directly warms plants and surfaces instead of the air.

Minimizes heat loss due to ventilation.

Perfect for greenhouses with high ceilings.

Energy-efficient for smaller spaces or specific areas.

Does not heat the air; may require additional heating in cold climates.

🌿 4. Soil Heating

How it works:

Under the growing beds, electric cables or hot water pipes are installed to heat the root zone.

This encourages healthy root development and aids in seed germination.

It may lower the need for extensive air heating.

Retrofitting existing greenhouses can be costly.

There is a risk of overheating if not properly monitored.

🌿 5. Biomass Heating

How it functions:

Utilizes wood pellets, chips, or agricultural waste to produce heat in a furnace.

A renewable energy source.

Economical in areas where biomass is inexpensive.

Requires fuel storage.

Demands more maintenance compared to traditional systems.

🌿 6. Solar Heating (Passive & Active)

Passive Solar:

Employs transparent glazing and thermal mass, such as water tanks and concrete, to capture and retain heat from sunlight.

Active Solar:

Utilizes solar collectors to heat water or air, which is then distributed to the greenhouse.

Decreases reliance on fossil fuels.

Can be combined with other systems for support.

Relies on the availability of sunlight.

Initial installation may be expensive.

⚡ Key Considerations When Choosing a Greenhouse Heating System

1. Greenhouse Size & Layout – Larger greenhouses often benefit from hydronic or forced-air systems.

2. Climate – Colder areas need more powerful heating systems, while milder climates might only require additional heating.

3. Plant Type – Certain plants, like tropical varieties, need precise temperature regulation.

4. Energy Costs & Availability – The choice of fuel (gas, electricity, biomass) influences operating expenses.

5. Automation – Contemporary greenhouses incorporate heaters with thermostats, sensors, and smart controls for improved efficiency.

Circulation fans greenhouse fans

🌿 1. Purpose of Circulation Fans

Circulation fans are essential for healthy plant growth in greenhouses because they:

Even out temperature: Prevent hot or cold spots in the greenhouse.

Prevent humidity buildup: Reduces risk of mold, mildew, and fungal diseases.

Strengthen plants: Gentle airflow stimulates stronger stems and roots.

Improve CO₂ distribution: Ensures plants get uniform access to CO₂ for photosynthesis.

🌿 2. Types of Circulation Fans

a) Horizontal Air Flow (HAF) Fans

Usually mounted high on walls or ceilings.

Create a horizontal airflow pattern that circulates air across the greenhouse.

Commonly used in commercial greenhouses.

Efficient for large spaces.

Reduces temperature gradients.

Requires careful positioning to avoid drafts directly on plants.

b) Oscillating Fans

Can be wall-mounted, floor-standing, or ceiling-mounted.

The head moves back and forth to circulate air over a wider area.

Flexible and adjustable.

Good for smaller greenhouses or zones needing more airflow.

Less uniform airflow in very large spaces.

c) Exhaust & Ventilation Fans

Usually mounted at one end of the greenhouse to remove hot or humid air.

Often paired with intake vents or evaporative cooling pads.

Controls temperature and humidity effectively.

Works well in combination with circulation fans.

Can create drafts if not balanced with intake airflow.

d) Propeller Fans / Tunnel Fans

Large fans used in tunnel-style or high-volume greenhouses.

Can create strong airflow to move large volumes of air quickly.

Effective in long greenhouses.

Often part of an automated climate control system.

Noise can be higher.

Requires proper mounting and safety measures.

🌿 3. Placement & Installation Tips

1. Height: Fans are usually mounted 2–3 meters above the plant canopy to prevent direct wind on plants.

2. Airflow pattern: Fans should push air in a circular or horizontal pattern rather than blasting in one direction.

3. Spacing: Depending on fan size and greenhouse dimensions, one fan per 200–400 m² is common, but large commercial setups may require more.

4. Integration: Ideally, circulation fans are linked to thermostats or climate control systems for automated operation.

5. Safety: Ensure guards are installed, and electrical connections are protected from humidity.

🌿 4. Best Practices

Run fans continuously or in intervals depending on plant type and environmental conditions.

Avoid cold drafts directly on sensitive plants.

Combine with heating and cooling systems for maximum climate stability.

Regular maintenance: Clean fan blades and check motors to ensure long-term efficiency.

Irrigation systems:

🌿 1. Purpose of Greenhouse Irrigation

Greenhouse irrigation provides

A steady water supply for plants.

Efficient nutrient delivery when combined with fertigation.

Conserves water by reducing waste.

Decreases plant stress from irregular watering.

🌿 2. Common Types of Greenhouse Irrigation

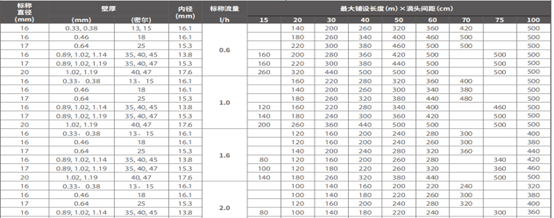

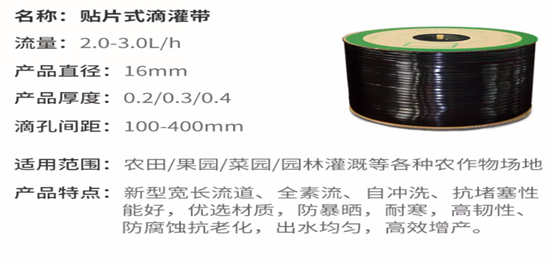

a) Drip Irrigation

Delivers water directly to the root zone through tubing and emitters.

Can be automated with timers or sensors.

Highly efficient in water usage, minimizing evaporation and runoff.

Suitable for row crops, vegetables, and high-value plants.

Can be used with liquid fertilizers (fertigation).

Filtration is necessary to prevent tube clogging.

Requires careful layout planning.

b) Sprinkler / Overhead Irrigation

Sprays water over the canopy using nozzles.

Quickly covers large areas.

Can provide foliar feeding.

Less efficient than drip due to evaporation and runoff.

Can increase humidity, which may lead to fungal diseases. Wetting leaves may not suit all crops.

c) Ebb and Flow (Flood & Drain)

Plants in trays are periodically flooded with nutrient solution and then drained.

Ensures uniform delivery of nutrients and water.

Highly automated, reducing manual labor.

Requires high setup costs.

Needs precise monitoring to prevent waterlogging.

d) Capillary Mat Irrigation

Plants rest on mats that draw water from a reservoir below.

Provides a gentle, consistent moisture supply.

Easy to install for small trays or seedling propagation.

Best for smaller plants or propagation trays.

Not ideal for large-scale crops.

e) Misting / Fogging Systems

Sprays fine droplets for humidity control and cooling.

Reduces plant stress during hot periods.

Beneficial for seedlings and delicate plants.

Increases humidity, which may encourage fungal diseases if overused.

🌿 3. Automation & Control

In contemporary greenhouses, irrigation systems are frequently fully automated:

Timers: Easily set up watering schedules.

Soil moisture sensors: Activate irrigation solely when needed.

16mm drip irrigation options include pressure compensated flat tape and round, as well as non-pressure compensated flat and round. Please provide photos and technical data sheets.

16mm start connectors and join connectors.

16mm.

Self cleaning disc filters photos.

MESH NET AND SHADING NET.

🌿 1. Purpose of Shading Nets

Shading nets are employed to manage light intensity and decrease heat within the greenhouse. They assist in sustaining optimal growing conditions by:

Avoiding overheating on hot days.

Minimizing light stress and leaf damage on plants.

Enhancing humidity retention.

Reducing evapotranspiration, thereby conserving water.

Establishing a more consistent microclimate throughout the greenhouse.

🌿 2. Types of Shading Nets

🟢 a) By Shading Percentage

The shade factor (%) of the net shows the amount of sunlight it obstructs.

Typical levels:

30–40% → suitable for crops that thrive in light (tomatoes, peppers).

50–60% → ideal for general vegetable cultivation.

70–80% → best for tropical plants or nursery propagation.

⚫ b) By Color

Color Use & Effect

Black Most common; reduces light and temperature efficiently.

Green Common in vegetable production; blends with environment.

White Reflects light evenly; reduces heat while keeping brightness.

Aluminet (reflective silver) Premium type; reflects heat radiation, lowers temperature, and diffuses light for uniform growth.

> Recommendation: For high-end vegetable or cannabis greenhouses, Aluminet 50–60% provides the best temperature and light control.

🌿 3. Installation Methods

a) External Shading Nets

Installed above the roof or on retractable frames.

Most effective for reducing solar load before it enters the structure.

Reduces internal heat buildup.

Improves cooling efficiency

% and 50% nethouse UV netting technical data sheet.

🦟 1. Purpose of Insect-Proof Nets

Insect-proof nets serve to physically prevent insects from entering the greenhouse, while still permitting air, light, and humidity to pass through.

These nets offer protection against:

Whiteflies

Aphids

Thrips

Leaf miners

Moths (such as Tuta absoluta)

Mosquitoes and other flying pests

Main goals:

Prevent pest entry.

Reduce pesticide use.

Maintain a stable microclimate for sensitive crops.

Improve overall crop quality and yield.

🧩 2. Mesh Sizes and Their Purpose

The mesh size (number of holes per inch) determines which insects are excluded.

Mesh (holes/inch) Approx. Opening (µm) Insects Blocked Typical Use

16–25 1000–600 µm Large insects (moths, beetles) Basic vegetable production

30–40 500–400 µm Whiteflies, aphids, leaf miners Most common general-use net

50–60 350–250 µm Thrips, small whiteflies High-protection greenhouses (tomatoes, cannabis, ornamentals)

70–80 200–150 µm Thrips, very small pests Research or high-value crops

> Recommendation for Rwanda:

Use 40–50 mesh (350–400 µm) for vegetables or cannabis — it balances airflow and pest exclusion effectively.

⚙ 3. Material & Quality

Material: UV-stabilized HDPE (High-Density Polyethylene) monofilament yarn.

Color: Transparent or light gray (white nets allow better light diffusion).

Weight: Typically, 80–130 g/m² depending on mesh density.

UV Resistance: 5–8 years under tropical sunlight.

🌬 4. Ventilation Considerations

Tighter mesh = better protection but reduced airflow.

Therefore, design must balance ventilation area and net resistance.

Design tips:

Increase total vent surface area by 25–40% when using fine (50–60 mesh) nets.

Use exhaust fans and circulation fans to maintain airflow.

Ensure no gaps between net frames and structure — insects can exploit even 2–3 mm openings

🏗 5. Istallation Methods

a) Fixed Nets

Installed permanently on side walls, roof vents, and air inlets.

Attached to aluminum or galvanized steel frames with clips or plastic profiles.

Pros: Simple, low maintenance.

Cons: Reduced flexibility for ventilation adjustment.

b) Roll-Up Nets (with Manual or Motorized System)

Common in tropical and semi-tropical greenhouses.

Nets installed on roll-up sides with plastic film for seasonal adjustment.

Pros: Allows maximum ventilation when insect pressure is low.

Cons: Slightly more maintenance and mechanical parts.

c) Double-Layer System

External net + internal insect barrier (often on openings).

Creates a "buffer zone" for maximum biosecurity.

Used in: Cannabis, export vegetable production, or seed propagation facilities

🌱 6. Integration with Climate Control

Combine with fans and cooling pads to maintain proper airflow.

Integrate with humidity and temperature sensors to prevent over-condensation.

Optional fogging/misting can compensate for airflow reduction.

Welcome to the future of greenhouse growing. We design and manufacture premium greenhouses tailored to each customer’s specific needs — delivering the highest standards of quality, precision, availability, and competitive pricing. Our advanced structures combine intelligent climate control, durable engineering, and energy-efficient design to ensure optimal performance in every environment. From concept to installation, we provide complete, customized solutions that empower growers to achieve maximum yields and year-round success.